Glam Pods

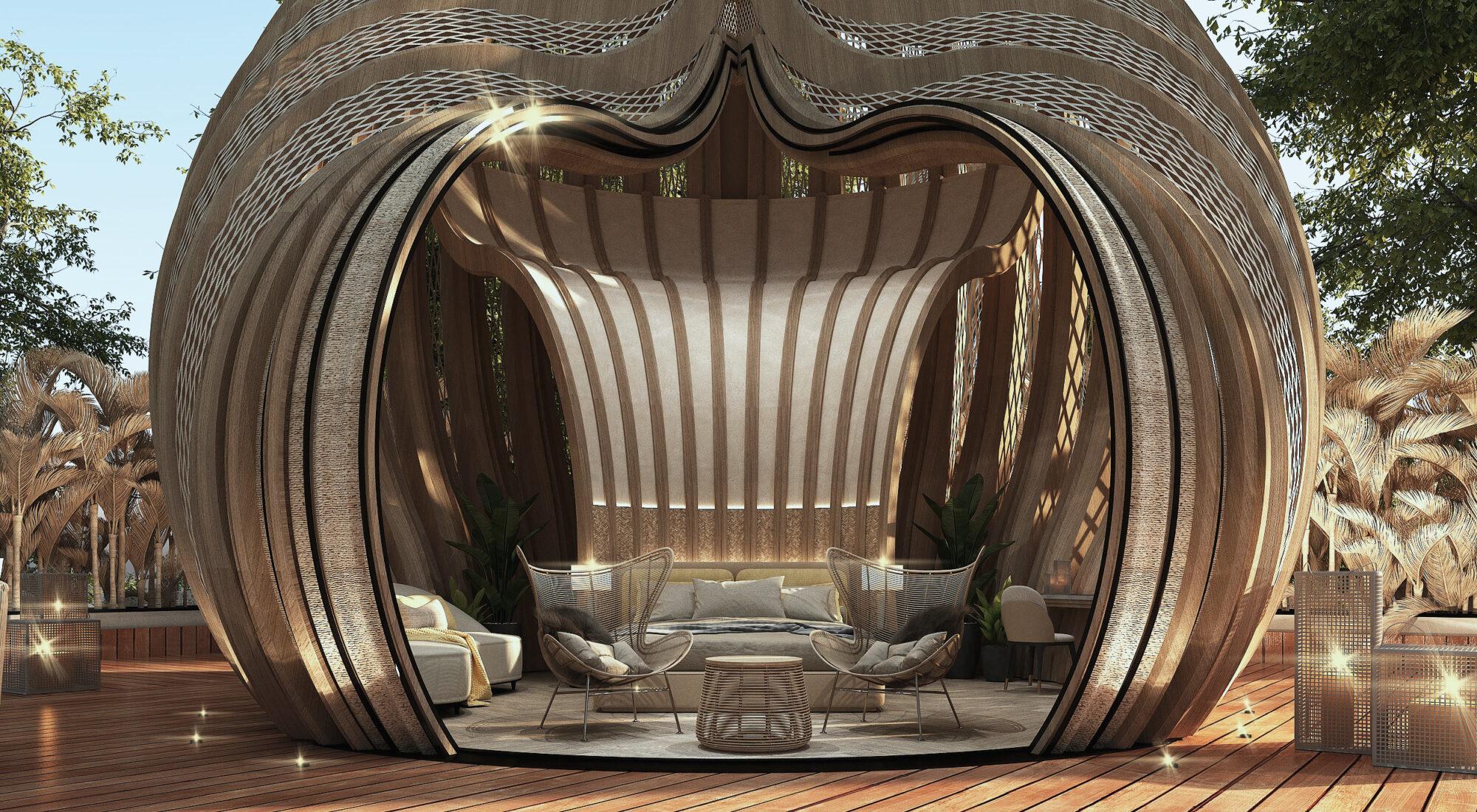

Global design firm WATG dreams up sustainable, 300 square-foot, 3D printed glamping pods that offer travelers the experience of nature immersion

-

Project Data

-

Location

Global

-

Size

300 square-feet

40-foot high -

Services

Wimberly Interiors

With the U.S. glamping industry projected to reach a revenue of $1 billion by 2024, Wimberly Interiors Los Angeles conceptualized an experience for guests to explore the joys of nature while fully immersing in the comfort of a luxurious yet sustainable glamping pod. Envisioned for ultra-remote locations, Glam Pods are a solution for everything from a backyard guest house to an off-the-grid lifestyle. Inspired by the spiraling coil of a shell, these 40-foot pods offer roughly 300 square-feet of total floor area, offering a space big enough for a king-size bed, lounge area and private bathroom.

The spines of the Glam Pods serve as their structural backbone, embodying naturally occurring patterns within a shell, also known as the Fibonacci sequence. The spines are composed of natural fibers for coloring that aesthetically provide a look of wood frames, which connect mesh “webbing” and allow natural light to engulf the space without compromising privacy. Lined within the webbing are translucent solar tiles that ignite enough energy to make each structure self-sustaining. Glam Pods are completely weather resistant and can withstand any climate, temperature or moisture condition.

Glam Pods’ interior design includes sought-after amenities like device-charging stations and a built-in solar-powered lighting with an eco-friendly smart-home feature that automatically turns off the lights when a guest leaves to explore for the day. An on-site restroom and walk-in closet are discreetly located in the back of each structure. Just like any five-star accommodation, Glam Pods will sport high-end furnishings, along with floor-to-ceiling windows to take full advantage of the surrounding view. Potential add-ons to the space could include wall hooks and a collapsible desk space for guests working remotely.

Aligning with green design strategies, Glam Pods employ natural ventilation through low-level inlet ventilators to supply outdoor air into the glamping pods’ interiors for proper ventilation and cooling in an energy efficient way. As warm air rises, it exits through high-level ventilators at the top. The large difference in height between the entry of fresh air and the exit of warm air creates a buoyancy effect that draws air through the structure. The primary purpose of natural ventilation is to allow the outside ambient weather to provide low humidity, and moderate temperature wind currents acts as an alternate cooling source for the building.

The construction of Glam Pods would be completed through 3D printing to enable mass production and customization, allowing full production to occur within one to three days. All glamping pods would be fully printed off-site and then shipped to a desired location where only furniture and utility hook-ups would be required. Rather than traditional construction, 3D printing reduces the amount of human labor and potential damage to a site, particularly in environmentally sensitive areas, allowing Glam Pods to be sustainably installed in far-flung locations. Intended to maintain the structural integrity of a cabin and the nimbleness of a camping tent, Glam Pods safely protect guests against potential storms and other natural weather occurrences.

Glam Pods are envisioned to be used either individually or collectively. For example, a family could obtain one and have it shipped to a desired location, or a landowner could acquire a series to create their own glamping compound, as pictured. A series of pods could be assembled on a joined deck that not only provides a polished terrace space for guests, but also cleverly conceals the below infrastructure to meet basic electric and plumbing needs. When no longer needed, Glam Pods’ spine material can be melted down and reused to potentially print more of the same, or other, 3D printed projects.

This design concept was developed by Troy Sayakumane and Zaher Arbash out of WATG’s Los Angeles office.

More Projects

- Europe

Mitsis Grand Hotel Rhodes

- China

Hyatt Regency Huangshan Hengjiangwan

- China

Hyatt Regency Huangshan Hengjiangwan

- North America

Tempo by Hilton, Nashville

- North America

Tempo by Hilton, Nashville

- Asia Pacific

Hilton Okinawa Miyako Island Resort

- Asia Pacific

Hilton Okinawa Miyako Island Resort

- Middle East

Nujuma, a Ritz-Carlton Reserve

- Middle East

Nujuma, a Ritz-Carlton Reserve

- North America

Burton House, Beverly Hills

- North America

Burton House, Beverly Hills

- North America

Four Seasons Private Residences Las Vegas

- North America

Four Seasons Private Residences Las Vegas

- North America

Pendry Newport Beach

- North America