WATG Confirms Testing Phase of Freeform 3D-Printed House

By WATG

January 22, 2018

Re-inventing the modern home

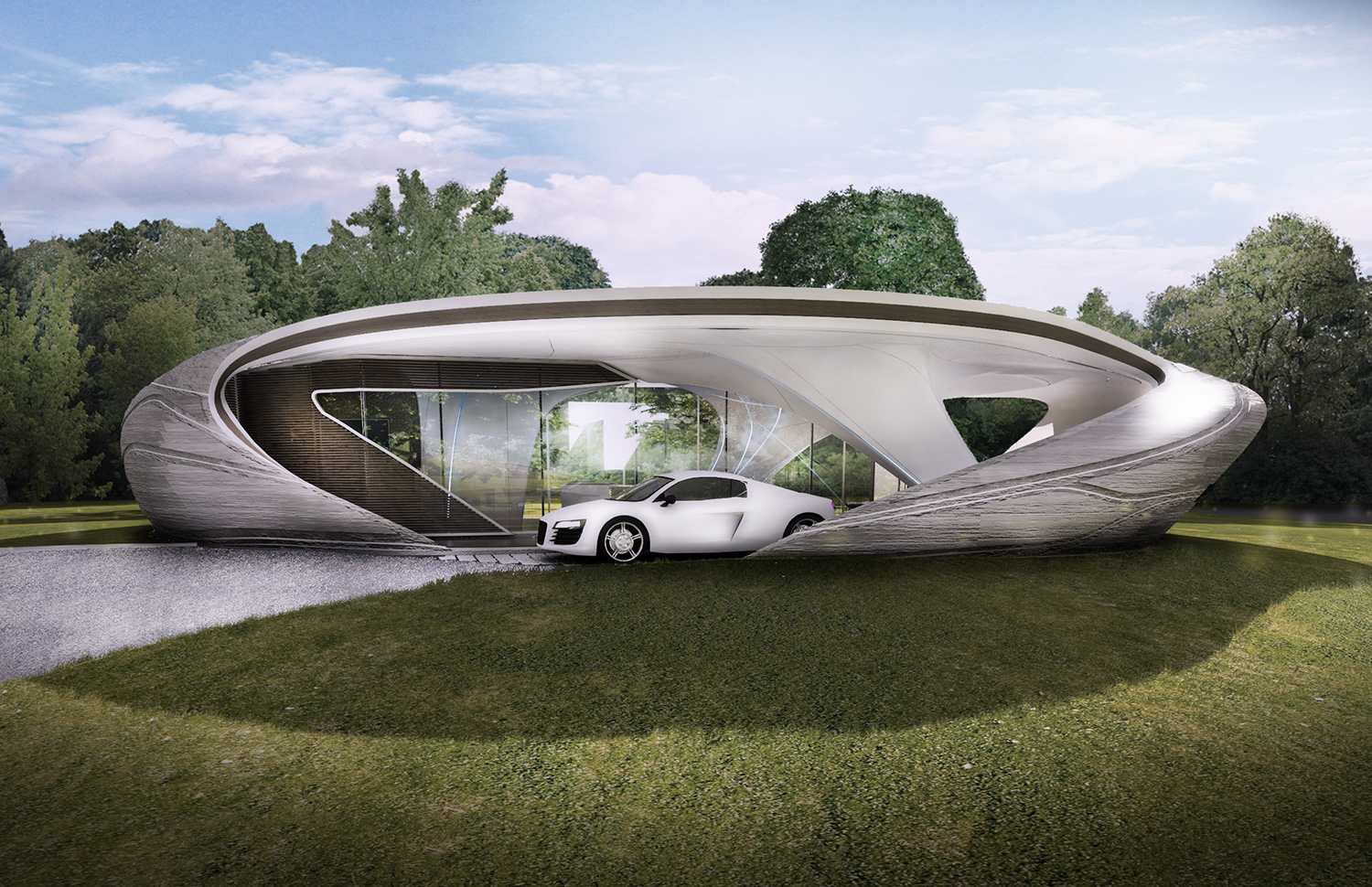

In 2016, the WATG Urban design team were awarded first prize in The Freeform Home Design Challenge; a competition commissioned by Branch Technology to design the world’s first freeform 3D printed house, which explores how 3D printing technology can improve our built environment and lives today.

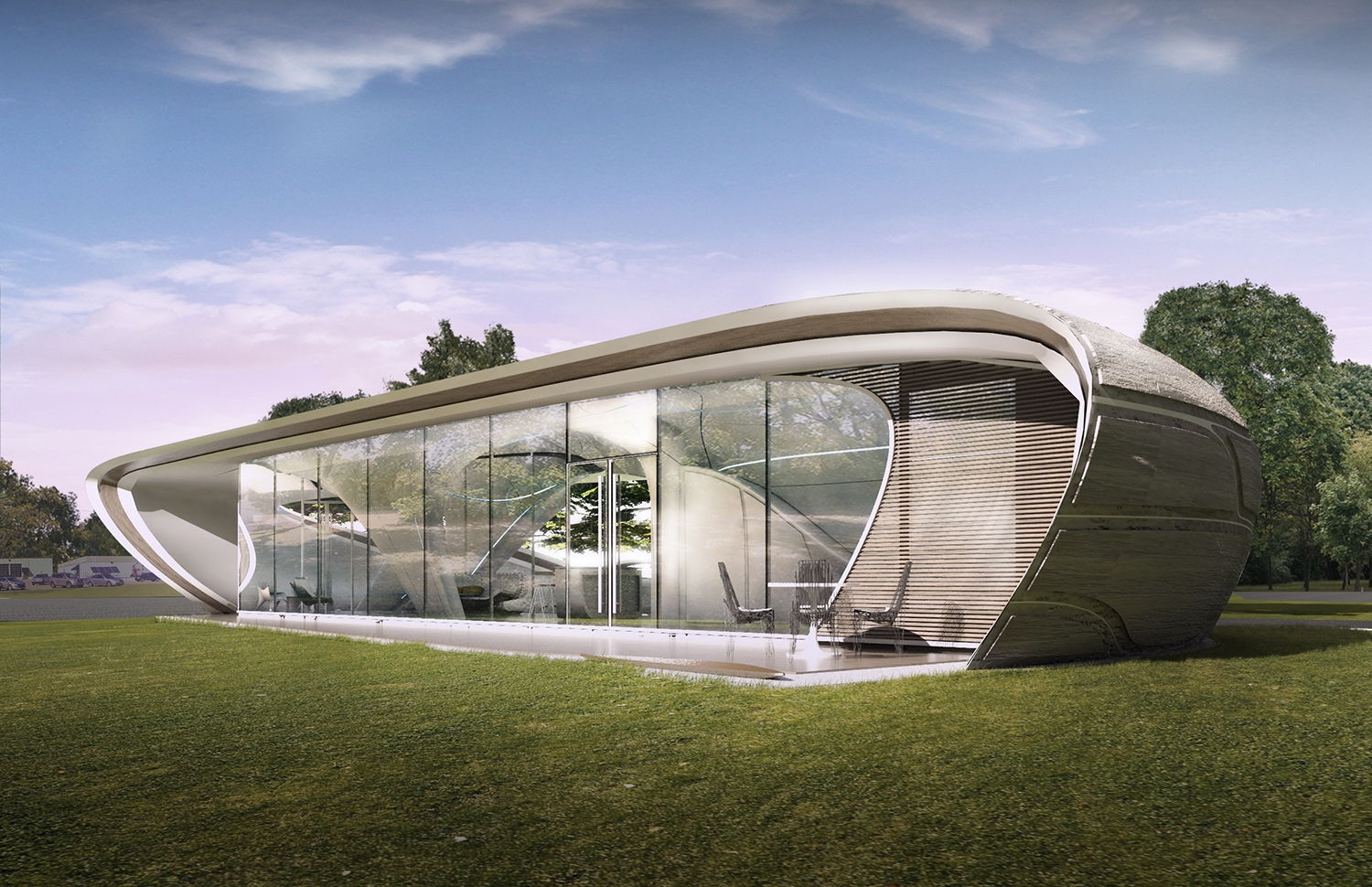

Over the last year, WATG’s Chicago office has been developing their design – Curve Appeal – with Branch Technology, and are thrilled to confirm that the wall section testing, research, and development phase of this revolutionary project is currently underway, working towards breaking ground later this year.

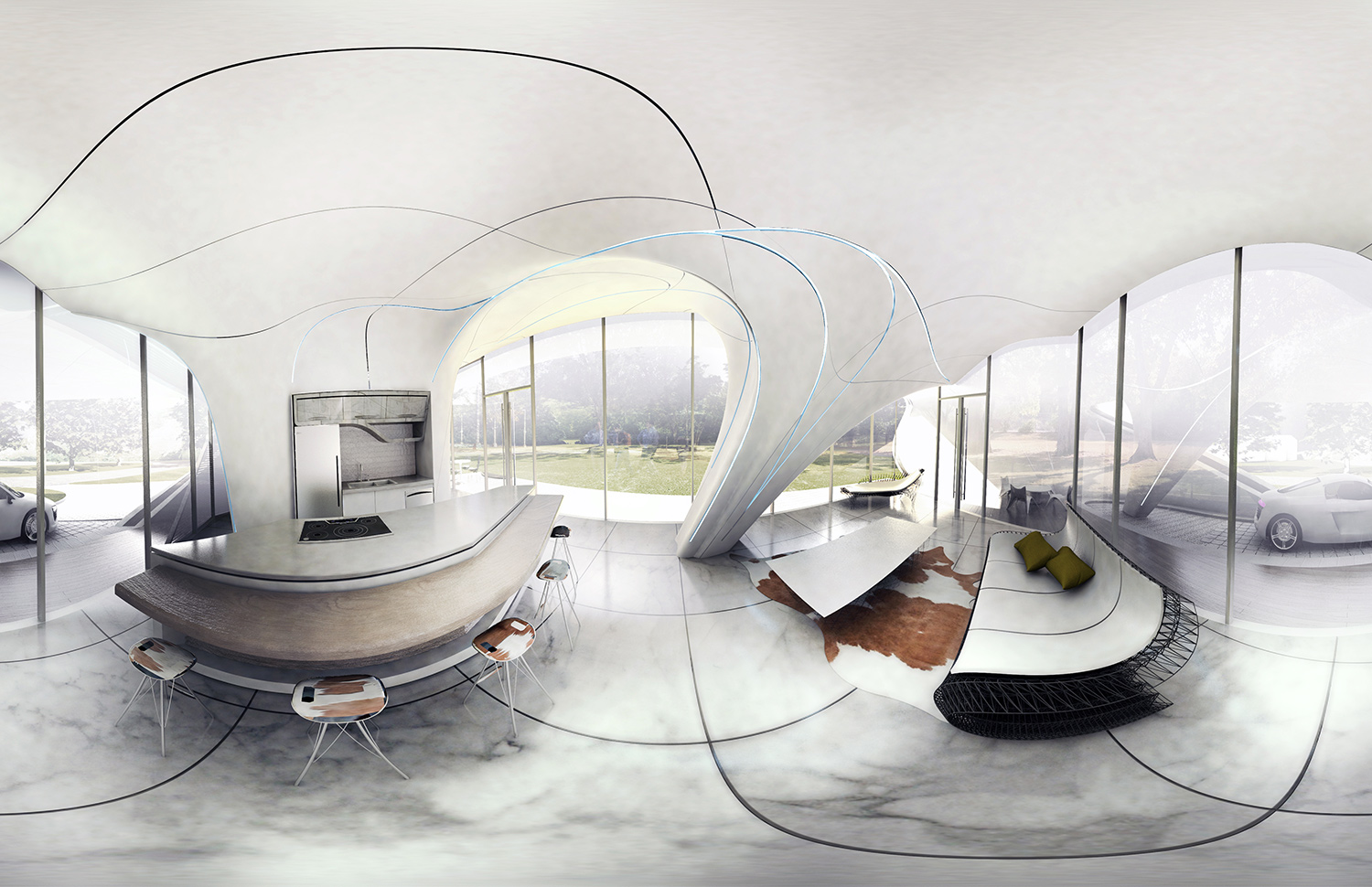

The design for Curve Appeal draws inspiration from the Case Study House program developed between 1945-1966. The program oversaw the design of 36 highly-experimental prototype residences, that could be constructed easily and efficiently, re-inventing the modern home. The architects leading the program were famed for constantly pushing the limits in terms of minimalist materials, and striving to create open-plan spaces that focused on enhancing natural light. Employing many of the same modernist design principles, Curve Appeal is the next evolutionary step, blurring the line between inside and out.

Using Branch Technologies’ Freeform™ printing process, complex design forms are no longer difficult or expensive to build. Within the home, the complex shell geometry is not only aesthetically attractive but structurally functional. The arching form provides structural rigidity to the residence, using various spring points throughout the floor plan, allowing the structure to carry roof loads and provide large open-plan living spaces, shaping structures in new ways without any restrictions.

Enlisting the services of Thornton Tomasetti, the team has been printing test beams and partial wall sections to examine their load bearing capabilities. In generic printed beam tests, a three-foot long beam could carry a load of approximately 3,600 pounds, while only weighing five pounds. The freeform printed matrix is essentially a small space frame, making it highly efficient. The next stage will be to test the maximum load bearing qualities of each individual printed element of the structure.

Working alongside United States Gypsum, WATG and Branch Technology have been researching a variety of gypsum material components [including gypsum spray foam and other innovative solutions provided by United States Gypsum’s research and development department] that could be applied on the printed structure to work as fire protection, structural reinforcement and to create a substrate for the application of finished wall materials. WATG and Branch Technology have engaged Interface, a high-performance mechanical, electrical and plumbing design firm, to design a passive mechanical system with the aim of making the house net zero-energy. That result of which is that the house will produce as much energy as it consumes, reducing its carbon footprint.

It’s important that the architecture and the environment work together harmoniously. The chosen site is steps away from the Tennessee River in a beautiful wooded, sunlit area. This allows the house to blend seamlessly into the environment, whilst also being naturally shaded and protected from solar radiation. WATG is currently producing detailed design drawings and working in collaboration with the City of Chattanooga to ensure the project is advancing according to the intended timeline.

Latest Insights

Perspectives, trends, news.

- News

Biocultural Conservation: Bridging Science and Design

- News

Biocultural Conservation: Bridging Science and Design

- Strategy & Research

Wimberly Interiors’ Interpret British Design: Eclectic, Modern with a Twist, Bespoke

- Strategy & Research

Wimberly Interiors’ Interpret British Design: Eclectic, Modern with a Twist, Bespoke

- Employee Feature

In Conversation: Sean Harry & Dan Hinch: The Intersection of Digital Practice & Landscape Architecture.

- Employee Feature

In Conversation: Sean Harry & Dan Hinch: The Intersection of Digital Practice & Landscape Architecture.

- Strategy & Research

Designing Destinations and Experiences that Last

- Strategy & Research