The World’s First Freeform 3D Printed House

By WATG

June 1, 2016

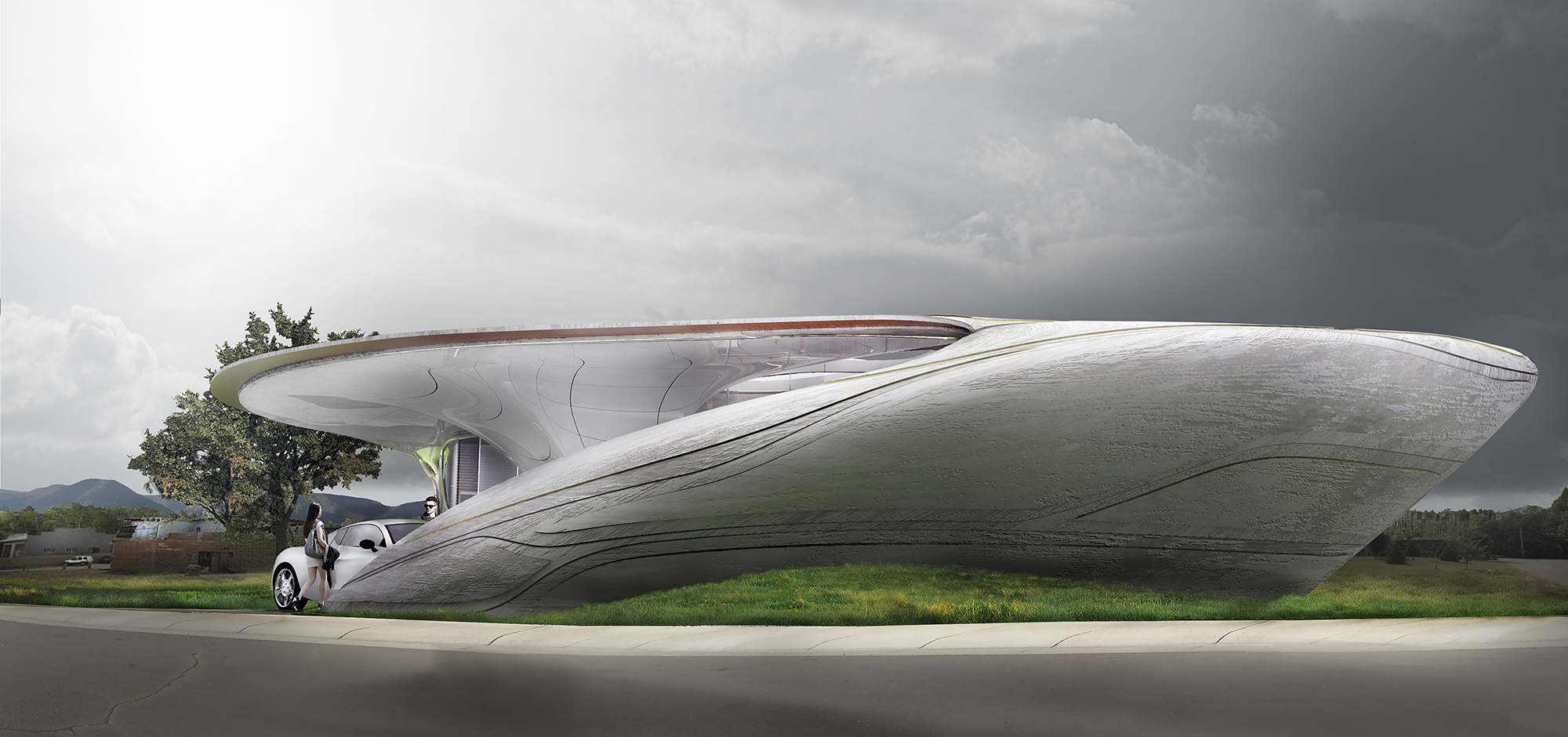

WATG’s innovative Urban Architecture Studio has won First Prize in the The Freeform Home Design Challenge, a competition to design the world’s first freeform 3D printed house.

The Freeform Home Design Challenge was conceived to invite architects, designers, engineers and artists from around the world to participate in an investigation of how 3D printing technologies can improve our built environment and lives today.

The challenge, commissioned by Branch Technology, was to design a 600-800 square-foot single-family home that would rethink traditional architectural aesthetics, ergonomics, construction, building systems, and structure from the ground up.

Branch Technology required participants to propose conceptual solutions for all aspects of the house. For example, the building envelope was to consider material applications, fenestration and structure. The interiors were to include a kitchen, bath, living area and one bedroom. In addition, building systems were to resolve mechanical, electrical, plumbing and lighting requirements while also allowing for passive solar design strategies.

WATG’s Chicago-based team, consisting of Daniel Caven, Chris Hurst, Miguel Alvarez and Brent Watanabe, won with their unique design, ‘Curve Appeal’. The proposal captures the potential for 3D printing to revolutionise design and construction. According to Branch Technology Founder, Platt Boyd, “Curve Appeal is a very thoughtful approach to the design of our first house. It responds well to the site conditions, magnifies the possibilities of cellular fabrication and pushes the envelope of what is possible while still utilizing more economical methods for conventional building systems integration.”

The design of the house consists of two main components: an interior core and exterior skin. The open and light filled interior living spaces protect occupants from the elements via passive strategies while connecting them to the exterior spaces and nature itself. The exterior skin is derived from simple yet careful calculated archways that ultimately blends with the site leaving an organic presence.

The house is set to begin planning phases in Chattanooga, Tennessee at Branch Technology’s lab and is expected to begin 3D printing in 2017.

About WATG

WATG is one of the world’s leading integrated design firms and ranked as 2nd in the world among hotel architectural firms. WATG’s interior design firm, Wimberly, was ranked 11th by Interior Design Magazine in their 2015 Hospitality Giants survey.

With over 70 years of design excellence, WATG and Wimberly, have become the world’s leading design consultants in the industry since starting in Hawaii in 1945. With offices in Irvine, Beverly Hills, Seattle, Chicago, New York, London, Miami, Istanbul, Dubai, Singapore, Shanghai and Honolulu, the multi-disciplinary design firm is best known for creating internationally acclaimed destinations in 160 countries across six continents. WATG offers integrated design solutions comprising strategy, planning, architecture, landscape, and interiors for urban, tourism and resort destinations. WATG’s projects are renowned not only for their design and sense of place but also for their bottom-line success.

About Branch Technology

Based in Chattanooga, Tennessee, USA, Branch Technology was founded by a group of architects and engineers with a vision to liberate design using their patented “Cellular Fabrication™” technology. Branch Technology™ has combined 3D Printing, industrial robotics, and conventional building materials to enable a new way to build. Cellular Fabrication™ is the next evolution of construction, using 3D printed structures as scaffolds, to which are applied conventional materials forming the structure, insulation, and finishes of a building. They are the first commercial entity to pursue construction-scale 3D printing and have the world’s largest freeform 3D printer.

The founders of Branch Technology believe that nature has unlimited creativity and that Cellular Fabrication™ allows virtually unlimited design freedom using economical construction materials for all construction projects to enjoy. They look to the natural world for inspiration. Like the muscles on our bones or trees in the forest, optimized geometries are made strong and functional by the material filling the matrix. It is concepts like these that motivate the Branch Technology team to liberate design.

Explore more at: Branch Technology

For more information please contact: WATG@purplepr.com

Latest Insights

Perspectives, trends, news.

- Strategy & Research

Wimberly Interiors’ Interpret British Design: Eclectic, Modern with a Twist, Bespoke

- Strategy & Research

Wimberly Interiors’ Interpret British Design: Eclectic, Modern with a Twist, Bespoke

- Employee Feature

In Conversation: Sean Harry & Dan Hinch: The Intersection of Digital Practice & Landscape Architecture.

- Employee Feature

In Conversation: Sean Harry & Dan Hinch: The Intersection of Digital Practice & Landscape Architecture.

- Strategy & Research

Designing Destinations and Experiences that Last

- Strategy & Research

Designing Destinations and Experiences that Last

- News

WATG receives top honors at LIV Hospitality Design Awards

- News